Forensic Engineers & Investigators

Adhesive And Composite Bonding

Some types of engineering components are often held together with chemical epoxy bonds. Examples are helicopter rotor blades (Aluminium bonded to Aluminium or stainless steel) or rubber covered steel rolls used in paper manufacturing processes and conveying equipment. (Rubber surface lining is bonded to steel roll)

From time to time these bonds fail. It is not always easy to determine whether or not they have failed due to excessive operating loads or because there have been deficiencies in manufacturing processes.

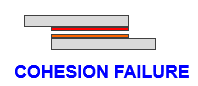

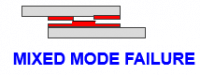

There are three different types of bond failures.

- Cohesion (or ‘cohesive’) failure. The bond fractures through the adhesive.

- Adhesion (or ‘adhesive’) failure. The bond fails along the interface between the adherends and the adhesive.

- Mixed-mode failures. This is a mixture of cohesion and adhesion failures. It is often misinterpreted as a cohesion failure, is the most common and the most difficult to interpret.

Adhesion failures and mixed mode failures are contributed to by poor manufacturing processes particularly inadequate preparation of the bonding surfaces prior to bonding. If this occurs, the adhesive does not chemically bond properly to the adherends and over time this allows the adherend surfaces to react with water vapour in the atmosphere and hydrate, causing the bond to delaminate and fail.We at Prosolve are world leading experts in engineering bonding science and adhesive bonding failures. We have the expertise and experience to characterise and determine the type of bonding failures and the engineering factors that have caused them. Below are two case studies of different types of bond failures.

Case Study 1: This photograph montage shows a fragment of a helicopter rotor blade exhibiting adhesion and mixed mode bonding defects. These were caused by deficient manufacturing processes such as inadequate surface preparation of the bonded pieces.

Case Study 2 : This photograph shows a rubber roll cover that has disbonded from its steel drum. This has been caused by deficient manufacturing processes particularly the use of inadequate surface preparation of the bonded surfaces.

These examples show failures that occurred despite the use industry accepted practices in surface preparation. This is a problem for the aviation and other industries that has still not been resolved.

Regrettably there is no reliable Non Destructive Testing (NDT) method to identify chemically weak bonds prior to failure and disbonding.

Max Davis, Patrick Conor and Andrew McGregor are engineering experts in this field who have made significant international contributions to address this problem. One such contribution was in the form of investigative findings of an accident that was investigated by Max Davis and Andrew McGregor. The FAA incorporated these findings into its FAA composite safety & certification initiative; A contribution to the FAA Composite safety and Certification initiative.

See also this ground braking paper written by Max Davis and Andrew McGregor; Assessing Adhesive Bond Failures Mixed Mode Bond Failures Explained